Bonals rotary presses

Bonals rotary tablet presses, essential equipment for industry

Rotary tablet presses are essential equipment in the compaction industry and offer a number of important features and advantages, enabling fast and efficient large-scale production.

Tablets

Wide variety of diameters and heights, as well as special sizes and shapes (blocks, layers and other shapes on request).

High-speed

Rotary presses enable continuous, high-speed production, resulting in increased efficiency and productivity.

Main advantages

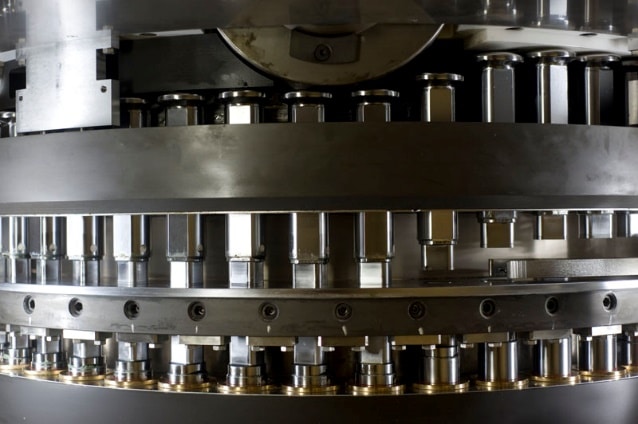

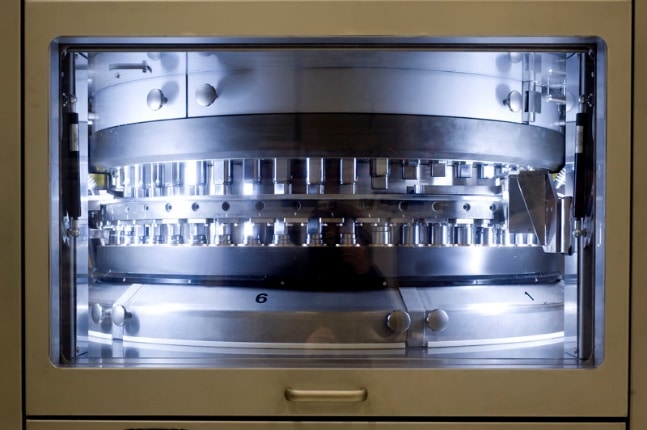

Our Rotary Presses in detail

Ventajas

Did you know that Rotary Presses…?

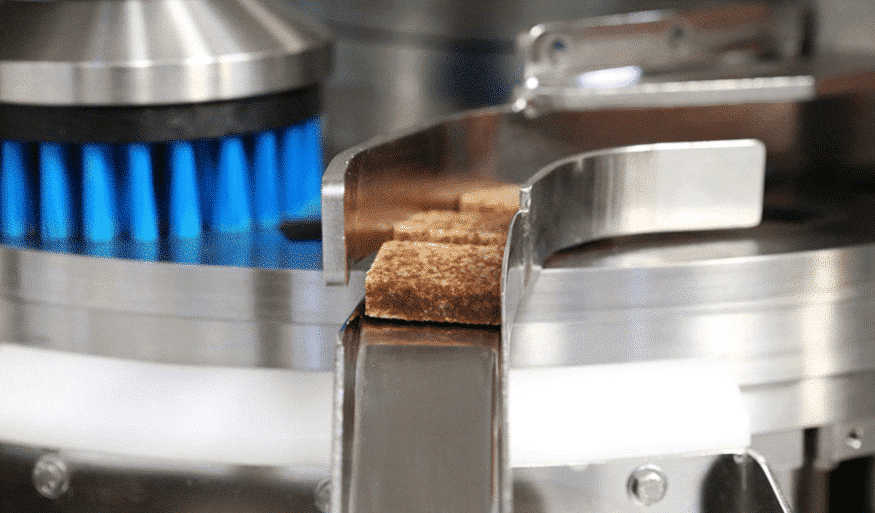

A curious fact about rotary presses is their amazing ability to produce tablets at a very high speed. To give an example, Bonals Technologies rotary presses are capable of producing up to 800 stock cubes or 600 tablets per minute.

This high-speed production capacity is only possible due to their efficient design and continuous production capability. In addition, the rotary presses feature automated monitoring and control systems that ensure consistency in dosing and tablet quality, which is essential to meet industry standards.

Get information without obligation

Frequently Asked Questions (FAQs)

What is a Rotary Press?

A rotary tablet press is a machine used to manufacture solid tablets from powders or granulates. It works by compressing powdered materials in dies to create tablets of specific shapes and sizes.

In which sectors are Rotary Presses used?

- Pharmaceutical Industry: Rotary presses are essential in the manufacture of pharmaceutical tablets, where they are used to compress powders or granulates into solid tablets.

- Food Industry: In the production of tablet or tablet products, rotary presses can be used to compact ingredients into specific shapes.

- Chemical Industry: In the manufacture of solid chemical products, such as cleaning products, pesticides, or industrial products, rotary presses can be used to compress the active ingredients into tablets or pellets.

- Cosmetics industry: In the manufacture of solid cosmetic products, such as soap bars, effervescent tablets, or skin care tablets, rotary presses can be used to shape the products.

How are Bonals Technologies Rotary Presses different?

Bonals Technologies has been specializing in rotary presses for over 113 years.

As a result, our rotary presses offer a high output of tablets per minute and minimal maintenance that gives our machines an unmatched production life.

Do you offer technical service or support for Rotary Presses?

Yes, we offer technical service whenever the customer needs it for the installation or maintenance of his rotary press.

How long does it take to supply and adapt the Rotary Press in a production plant?

Rotary presses, depending on the capacity, usually take between 4-6 months. For a more accurate estimate, please contact us without any obligation.